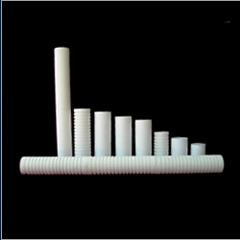

Grooved Filter Cartridge

Product Details:

- Sealing Silicone, EPDM, NBR, Viton

- Filter Media Polypropylene, Cellulose, Glass Fiber (as required)

- Shape Cylindrical

- Pore Size Standard as per specification

- Filter Rating 1 to 100 micron

- Product Type Grooved Filter Cartridge

- Material Polypropylene

- Click to View more

Grooved Filter Cartridge Price And Quantity

- 225.00 INR/Piece

- 100 , , Piece

Grooved Filter Cartridge Product Specifications

- Water filtration, Chemical processing, Food & Beverage, Pharmaceuticals

- Polypropylene

- Standard as per specification

- Filter Cartridge

- Cylindrical

- Up to 99.9%

- Grooved

- 1 to 100 micron

- Polypropylene, Cellulose, Glass Fiber (as required)

- Grooved Filter Cartridge

- Silicone, EPDM, NBR, Viton

Grooved Filter Cartridge Trade Information

- 100 , , Piece Per Week

- 1 Week

- All India

Product Description

Pertaining to the clients requirements, we are engaged in manufacturing and supplying quality assured Grooved Filter Cartridge. This cartridge is manufactured using superior quality raw material in order to win the trust of clients. Available in different sizes and thickness, this cartridge is highly demanded in the global market. To ensure secure shipment, this cartridge is delivered with the help of our reliable carriage & freight personnel within the promised time frame. This Grooved Filter Cartridge is ideal for water filter applications.

Various characteristics of Grooved Filter Cartridge:

- Excellent material strength

- Simple to fit

- Durability

- Perfect finish

Product details

Enhanced Efficiency and Capacity: With their innovative grooved surface, these filter cartridges provide an expanded surface area, resulting in higher dirt-holding capacity and minimal pressure drop. Available in multiple lengths and filter ratings (1 to 100 micron), they effectively trap contaminants while maintaining optimal flow (up to 100 LPM depending on configuration). This design ensures extended service life and consistent filtration performance in demanding applications.

Versatile Construction for Critical Applications: Manufactured using polypropylene, cellulose, or glass fiber as needed, these cartridges are compatible with a wide array of liquids and chemicals. Their autoclavable construction ensures sterilityvital for pharmaceuticals and food processing. Multiple end cap (DOE, SOE, customized) and sealing options (Silicone, EPDM, NBR, Viton) provide secure, leak-free installation in varied system setups.

FAQs of Grooved Filter Cartridge:

Q: How do the grooved filter cartridges enhance filtration performance?

A: The grooved design significantly increases the filters surface area, allowing it to trap more dirt and particles before requiring replacement. This results in higher dirt-holding capacity, improved efficiency, and extended cartridge life compared to standard smooth filters.

Q: What applications are Grooved Filter Cartridges most suitable for?

A: These cartridges are ideal for water purification, chemical processing, pharmaceutical production, and food & beverage industries. Their construction materials and autoclavable feature make them compatible with both standard and high-purity applications.

Q: When should I replace the grooved filter cartridge?

A: Replace the cartridge when a significant pressure drop occurs across the filter or when the desired filtration quality declines. The actual replacement interval depends on the flow rate, contamination level, and grade used, but regular monitoring is essential for best results.

Q: Where can these filter cartridges be installed?

A: They can be fitted into standard filter housings that match the cartridges length (10", 20", 30", or 40") and 63 mm diameter. End cap styles (DOE, SOE, customized) and seals accommodate most industrial, municipal, or commercial systems in India and abroad.

Q: What process is used for sterilizing the filter cartridges?

A: The cartridges are autoclavable and can be sterilized by subjecting them to high-pressure steam without damaging their structure, making them suitable for sterile processing environments, especially in pharmaceuticals and food & beverage industries.

Q: How do I choose the correct filter rating and length for my application?

A: Select the filter rating (1 to 100 micron) based on the particle size you need to remove. Cartridge length affects dirt capacity and flow rate longer cartridges handle greater volumes and typically last longer between changeouts.

Q: What are the benefits of using a polypropylene core and advanced sealing options?

A: A polypropylene core provides high chemical resistance and structural stability. Advanced sealing materials, such as Silicone, EPDM, NBR, or Viton, ensure a secure and leak-proof installation, compatible with varied process fluids and temperature conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Filter Cartridge' category

|

KALBAG FILTERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |