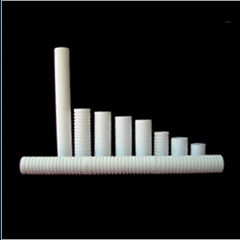

Resin Bonded Filter Cartridges

Product Details:

- Pore Size Graded pore structure, 1 to 150 micron

- Shape Cylindrical

- Filter Media Cellulose, Phenolic Resin

- Product Type Resin Bonded Filter Cartridges

- Material Other

- Type Depth filter cartridge

- Cartridge Style Single open end (SOE), Double open end (DOE)

- Click to View more

Resin Bonded Filter Cartridges Price And Quantity

- 225.00 INR/Piece

- 100 , , Piece

Resin Bonded Filter Cartridges Product Specifications

- Single open end (SOE), Double open end (DOE)

- Cylindrical

- Industrial liquid filtration, Oil filtration, Water treatment, Chemical processing

- Graded pore structure, 1 to 150 micron

- Depth filter cartridge

- Cellulose, Phenolic Resin

- Resin Bonded Filter Cartridges

- Up to 99% for target particle size

- Other

Resin Bonded Filter Cartridges Trade Information

- 100 , , Piece Per Week

- 1 Week

- All India

Product Description

Enriched with vast industry experience, we have been committed to manufacture and supply a wide range of Resin Bonded Filter Cartridges. To attain complete customer satisfaction, we assure to use one best quality materials that are sourced from accredited vendors of the market. We duly check these cartridges on various factors like resistance against leakage and material strength. These Resin Bonded Filter Cartridges are extensively used for air filtration applications.

Feature of Resin Bonded Filter Cartridges-

- Durability

- Simple fitting

- High tensile strength

Available in variety of sizes from 100 to 0.1 microns.

Engineered for Industrial Liquid Filtration: Our Resin Bonded Filter Cartridges deliver robust performance in challenging industrial environments. Designed for versatility, these cartridges accommodate a wide pH range and high temperatures, making them suitable for water, oils, chemicals, and solvents. The sturdy thermoplastic or phenolic resin end caps ensure consistent sealing and durability during prolonged operations.

Graded Pore Structure for Optimal Filtration: Featuring a carefully engineered graded pore structure, these cartridges efficiently capture particles as small as 1 micron and up to 150 microns, achieving removal efficiencies exceeding 99% for the desired particulate size. The depth filter design maximizes contaminant retention and extends cartridge service life, reducing downtime and replacement frequency.

FAQs of Resin Bonded Filter Cartridges:

Q: How are resin bonded filter cartridges installed in filter systems?

A: Resin bonded filter cartridges are designed to fit standard filter housings and can be installed using either the single open end (SOE) or double open end (DOE) configurations. Simply insert the cartridge into the housing, ensuring compatibility with the inlet and outlet diameters as specified, and secure the housing for operation.Q: What fluids can these cartridges effectively filter?

A: These cartridges are engineered for broad chemical compatibility and can filter water, oils, chemicals, and solvents. Their robust construction allows reliable filtration in diverse industrial applications such as water treatment, oil filtration, and chemical processing.Q: When should I replace my resin bonded filter cartridge?

A: Replacement depends on factors such as the fluid type, contaminant load, flow rate, and cartridge length. Typically, the cartridge should be replaced when there is a noticeable drop in flow rate or a significant increase in differential pressure, ensuring continued high removal efficiency.Q: Where can resin bonded filter cartridges be used?

A: These cartridges are suitable for a variety of industrial environments, including water treatment plants, oil refineries, and chemical processing facilities. Their chemical resistance (pH 113) and temperature durability (up to 120C) make them adaptable to demanding filtration scenarios.Q: What is the benefit of using cellulose fiber with phenolic resin bonding?

A: The combination of cellulose fiber and phenolic resin bonding creates a strong, dimensionally stable matrix with excellent compatibility across a range of fluids. This design ensures efficient particulate removal, reduced channeling, and longer service life compared to conventional filters.Q: How does the graded pore structure enhance filtration?

A: A graded pore structure means that larger particles are captured on the outside, while progressively smaller particles are trapped deeper within the cartridge. This multilayer approach maximizes dirt-holding capacity and extends the filters operational life without compromising efficiency.Q: What is the maximum operating temperature and pressure for these cartridge filters?

A: These cartridges operate reliably at temperatures up to 120C (248F) and can withstand pressures up to 6 bar. This makes them suitable for a wide range of industrial filtration processes involving hot or pressurized fluids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Filter Cartridge' category

|

KALBAG FILTERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |