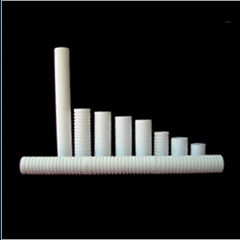

Meltblown Filter Cartridges for Water Filter

Product Details:

- Sealing Gasket

- Filter Rating 1 - 100 micron

- Filter Media Polypropylene Meltblown

- Shape Cylindrical

- Pore Size 1 - 100 micron

- Product Type Filter Cartridge

- Material Polypropylene

- Click to View more

Meltblown Filter Cartridges for Water Filter Price And Quantity

- 100 , , Piece

- 225 INR/Piece

Meltblown Filter Cartridges for Water Filter Product Specifications

- 1 - 100 micron

- Water Filtration

- Polypropylene

- 99%

- Gasket

- Meltblown

- Cylindrical

- Polypropylene Meltblown

- Standard

- 1 - 100 micron

- Filter Cartridge

Meltblown Filter Cartridges for Water Filter Trade Information

- 100 , , Piece Per Week

- 1 Week

Product Description

Melt Blown Filter Cartridges for Water Filter are cylindrical cartridges made from the finest polymer fibers melt blown and collected over a rotating spindle. These fibers are collected on the rotating spindle to form a gradient structure and then pressed and sintered. The randomly deposited fibers form a nonwoven sheet product applicable for filtration, sorbents, apparels and drug delivery systems. Melt Blown Filter Cartridges for Water Filter uses a conventional fabrication method of micro- and nanofibers where a polymer melt is extruded through small nozzles surrounded by high speed blowing gas.

Usage : Water Filter, Prefilter for Industrial RO

High-Efficiency Filtration: Meltblown filter cartridges achieve up to 99% efficiency in removing particulates and contaminants from water, securing clean water for a range of uses. The polypropylene construction ensures chemical resistance, making these filters suitable for domestic, industrial, and commercial applications where water quality is paramount.

Flexible Sizing and Installation: With cartridge lengths of 10", 20", 30", and 40", and a standard 2.5" diameter, these filters fit a vast array of water systems. Their coreless design and compatibility with both DOE and SOE end caps offer convenient installation in vertical or horizontal orientations, matching different filtration units and requirements.

Durable and Economical Solution: Engineered for use under pressures up to 4 bar and temperatures reaching 80C, these cartridges are robust and dependable. The recommended replacement interval of 612 months, depending on usage, keeps system maintenance straightforward and cost-effective for users across domestic, industrial, or commercial environments.

FAQs of Meltblown Filter Cartridges for Water Filter:

Q: How should I install a Meltblown Filter Cartridge in my water filtration system?

A: Installation is straightforward: align the cylindrical cartridge with the system housing, ensuring the end caps (DOE or SOE) fit correctly, and insert vertically or horizontally as per your setup. Always check the compatibility with your filter unit before installation.Q: What types of contaminants do Meltblown Filter Cartridges remove from water?

A: These cartridges efficiently remove sediments, particulates, rust, and other suspended solids from water. The filter rating and pore size (1 to 100 microns) allow you to target specific contaminants according to your applications needs.Q: When should I replace my Meltblown Filter Cartridge?

A: Cartridges should be replaced every 6 to 12 months, depending on water quality and usage volume. Indicators for replacement include noticeable decreased flow rate or visible clogging, which can affect efficiency.Q: Where can Meltblown Filter Cartridges be used?

A: They are suitable for domestic, industrial, and commercial environments requiring water filtrationideal for homes, factories, commercial kitchens, and more. Ensure compatibility with your filtration systems specifications for optimal performance.Q: What is the benefit of using coreless and polypropylene meltblown filter media?

A: Coreless design reduces waste and makes disposal easier, while polypropylene meltblown media offers high filtration efficiency, chemical resistance, and durability, optimizing both performance and environmental impact.Q: How does the maximum flow rate vary with cartridge length and micron rating?

A: The maximum flow rate can reach up to 3 m/h, but this depends on the cartridges micron rating and length. Finer micron ratings and longer cartridges typically have lower flow rates due to higher filtration efficiency.Q: What maintenance is required during the cartridges service life?

A: Routine maintenance involves monitoring water quality and pressure drop. If you notice a significant decrease in flow or increased pressure differential (up to the 2 bar maximum), its time to clean the system and consider replacing the cartridge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Filter Cartridge' category

|

KALBAG FILTERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |